Welcome to the Mitsubishi Industrial Air Conditioner Manual, your comprehensive guide to understanding, installing, and maintaining Mitsubishi industrial air conditioning systems․ This manual provides essential information to ensure optimal performance, energy efficiency, and safety․

Overview of Mitsubishi Industrial Air Conditioners

Mitsubishi industrial air conditioners are advanced systems designed for large-scale cooling in factories, warehouses, and commercial spaces․ Known for energy efficiency and durability, these units are built to withstand rigorous industrial demands․ They utilize cutting-edge technology to maintain consistent temperatures, ensuring optimal working conditions and equipment longevity․ Mitsubishi systems are popular for their reliability, low operational noise, and eco-friendly designs․ They cater to diverse industrial needs, offering scalable solutions for varying space sizes and cooling requirements․ With a focus on innovation and sustainability, Mitsubishi industrial air conditioners are a trusted choice for businesses seeking robust and efficient climate control solutions․

Key Features of Mitsubishi Industrial Air Conditioner Models

Mitsubishi industrial air conditioner models are equipped with cutting-edge features tailored for industrial environments․ High-capacity cooling systems ensure consistent temperature control, while advanced inverter technology optimizes energy consumption․ These models often include robust compressors designed for heavy-duty operation and long lifespan․ Smart sensors monitor performance, adjusting settings for peak efficiency․ Mitsubishi units also feature anti-corrosion coatings to withstand harsh industrial conditions․ Additionally, they offer programmable controls and remote monitoring capabilities, allowing seamless integration into industrial automation systems․ Enhanced filtration systems improve air quality, and silent operation reduces workplace noise․ These features make Mitsubishi air conditioners a reliable and efficient choice for demanding industrial applications, ensuring both performance and durability․

Understanding the Manual’s Structure and Content

This manual is structured to provide a comprehensive guide for Mitsubishi industrial air conditioner users․ It begins with an introduction, followed by detailed sections on installation, maintenance, and troubleshooting․ Each chapter is designed to address specific needs, ensuring ease of navigation․ The manual includes technical specifications, safety guidelines, and operational instructions․ Diagrams and charts are incorporated to clarify complex procedures․ Additionally, it contains a troubleshooting section to help diagnose and resolve common issues․ The content is organized logically, making it accessible for both professionals and end-users․ By following the manual, users can ensure optimal performance, safety, and longevity of their Mitsubishi industrial air conditioning systems․ This structured approach guarantees that all aspects of the unit are covered comprehensively․

Installation and Setup Guidelines

Proper installation ensures efficient operation․ Follow site preparation, alignment, and electrical connection guidelines․ Ensure all components are securely fastened and tested before operation begins for optimal functionality․

Pre-Installation Requirements and Site Preparation

Before installing your Mitsubishi industrial air conditioner, ensure the site is properly prepared․ Verify power supply compatibility, including voltage, phase, and circuit breaker requirements․ Ensure the installation area is level, well-ventilated, and accessible for maintenance․ Check for any obstructions or hazards that could interfere with installation or operation․ Confirm that the floor or mounting structure can support the unit’s weight․ Plan for proper drainage, especially for units that produce condensate․ Ensure all necessary tools and materials are available․ Review local building codes and regulations to comply with installation standards․ Proper site preparation ensures a smooth installation process and optimal system performance․

Step-by-Step Installation Process

Begin by unboxing and inspecting the unit for any damage․ Mount the base plate securely to the floor or structure, ensuring it is level․ Install the condenser and evaporator units in their designated areas․ Connect refrigerant lines, ensuring proper sizing and insulation․ Route electrical cables according to the wiring diagram, making sure all connections are tight․ Install any necessary drainage systems for condensate removal․ Mount the control panel and connect it to the main unit․ Perform a vacuum test on the refrigerant lines to eliminate air and moisture․ Charge the system with refrigerant if required․ Finally, power up the system and test all functions to ensure proper operation․ Always follow manufacturer guidelines and safety protocols during installation․

Initial Setup and Configuration

After installation, power up the unit and allow it to run through its initial startup sequence․ Check the default settings on the control panel, such as temperature, fan speed, and operating mode․ Configure the thermostat to your desired settings, ensuring it is synchronized with the main unit․ Test all functions, including cooling, heating, and fan-only modes, to ensure proper operation․ Program the timer and scheduling features if available․ Familiarize yourself with the remote control or centralized control system, if applicable․ Finally, review and adjust any additional settings, such as airflow direction or energy-saving modes, to optimize performance for your specific needs․ Always refer to the manual for specific button sequences and configuration options․

Maintenance and Troubleshooting

This section covers essential maintenance routines and troubleshooting tips to ensure your Mitsubishi industrial air conditioner operates efficiently and reliably over its lifespan․ Regular filters cleaning, coil inspections, and condensate drain checks are vital for optimal performance․ Addressing common issues like error codes or reduced airflow promptly prevents major malfunctions․ Refer to the manual for detailed diagnostic guides and repair procedures to maintain your system’s peak condition and extend its service life effectively․

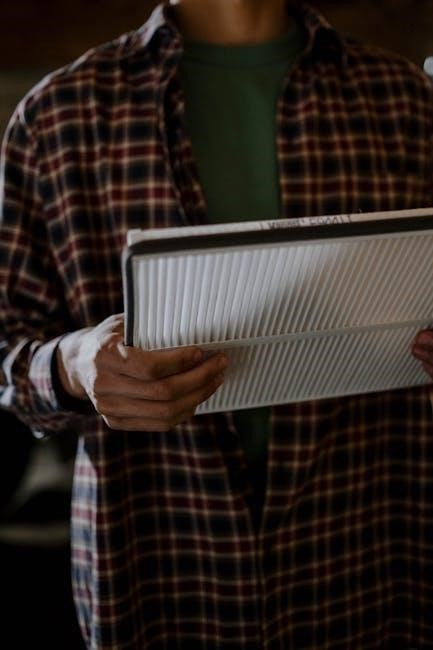

Regular Maintenance Tasks for Optimal Performance

Regular maintenance is crucial for ensuring your Mitsubishi industrial air conditioner operates efficiently and effectively․ Start with cleaning or replacing air filters monthly to improve airflow and reduce energy consumption․ Inspect and clean condenser coils every three months to prevent dirt buildup that can hinder heat transfer․ Check and tighten electrical connections to avoid malfunctions․ Lubricate fan motors annually to maintain smooth operation and reduce wear․ Drain and inspect condensate pans to prevent water damage and mold growth․ Schedule professional inspections annually to address hidden issues․ By following these routines, you can enhance performance, reduce energy costs, and extend the system’s lifespan․ Consistency is key to maintaining optimal functionality․

Common Issues and Troubleshooting Techniques

Mitsubishi industrial air conditioners are reliable, but occasional issues may arise․ Common problems include insufficient cooling, water leaks, or error codes․ For insufficient cooling, check if air filters are clean and ensure proper thermostat settings․ Water leaks often result from clogged condensate drains, which can be resolved by clearing blockages․ Error codes should be addressed by consulting the manual or contacting a technician․ Additionally, ensure all electrical connections are secure and verify refrigerant levels․ Regularly inspecting components like fans and coils can prevent overheating issues․ If problems persist, refer to the troubleshooting section of this manual or contact Mitsubishi support for professional assistance․ Prompt resolution ensures uninterrupted operation and system longevity․ Always follow safety guidelines when diagnosing or repairing issues․

Optimizing Energy Efficiency and Performance

To maximize the energy efficiency and performance of your Mitsubishi industrial air conditioner, ensure proper installation and regular maintenance․ Clean air filters and condenser coils regularly to prevent dust buildup, which can reduce efficiency․ Adjust thermostat settings to balance comfort and energy savings․ Utilize advanced features like inverter technology for variable-speed operation, which optimizes cooling while minimizing energy consumption․ Properly insulate ducts and ensure they are sealed to prevent energy loss․ Use programmable thermostats to manage temperatures during off-hours or low-occupancy periods․ Additionally, consider upgrading to smart sensors that automatically adjust settings based on occupancy and environmental conditions․ These strategies will help reduce energy costs, prolong equipment life, and maintain consistent cooling performance․ Always refer to the manual for model-specific optimization tips․ Regular maintenance is key to sustaining peak efficiency and performance․

Safety and Compliance

Adhere to safety guidelines and industry standards for proper installation and operation of Mitsubishi industrial air conditioners․ Ensure compliance with local regulations to maintain reliability and minimize risks․

Safety Precautions When Handling the Air Conditioner

When handling Mitsubishi industrial air conditioners, always wear protective gear, including gloves and safety glasses․ Ensure the unit is powered off before performing any maintenance or repairs․ Avoid overheating components by following proper shutdown procedures․ Keep flammable materials away from the unit to prevent fire hazards․ Never attempt to modify or bypass safety features, as this can lead to system malfunctions or personal injury․ Refer to the manual for specific guidelines on handling refrigerants and electrical components safely․ Proper grounding and ventilation are essential to avoid electrical shocks and gas leaks․ Always follow industry safety standards to ensure a secure working environment․

Compliance with Industry Standards and Regulations

Mitsubishi industrial air conditioners are designed to meet or exceed global industry standards and regulations․ These systems comply with energy efficiency standards set by organizations like ENERGY STAR and ASHRAE․ They also adhere to environmental regulations, including those related to refrigerant use and emissions, as outlined in the Clean Air Act․ Additionally, Mitsubishi units meet safety certifications from bodies like UL (Underwriters Laboratories) and ETL (Intertek)․ Compliance ensures reliability, sustainability, and adherence to local and international laws․ Always verify that your system meets the specific standards required by your region or industry․ Proper compliance guarantees optimal performance and minimizes environmental impact․

Thank you for reviewing the Mitsubishi Industrial Air Conditioner Manual․ Proper installation, maintenance, and compliance ensure optimal performance and longevity․ Refer to this guide for troubleshooting and efficiency tips․

Final Tips for Effective Usage and Longevity

For maximum efficiency and longevity, ensure regular maintenance, proper installation, and adherence to the manual’s guidelines․ Monitor performance and address issues promptly to prevent damage․ Schedule professional inspections annually to maintain optimal functionality․ Keep the system clean, and replace filters as recommended to improve air quality and energy efficiency․ Avoid extreme temperature settings to reduce wear and tear․ By following these tips, you can extend the lifespan of your Mitsubishi industrial air conditioner while ensuring reliable performance and energy savings․ Always refer to the manual for specific instructions tailored to your model․